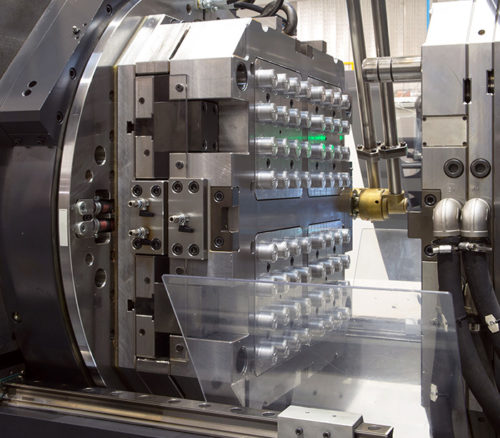

At Daystar Manufacturing, we specialize in plastic injection molding solutions. Plastic injection molding is a manufacturing process that creates molded parts and products by injecting molten plastic into molds and allowing it to cool and solidify. It is a cost-effective option for producing components with complex shapes in high volumes.

Our Plastic Injection Molding Capabilities

This equipment accommodates a range of plastic materials, including commodity-grade plastics and polymers (polypropylene, polyethylene, polystyrene) and engineering materials (nylons, polycarbonates, ABS). It enables our team to produce parts and products to tight tolerances (±.0005 inches, depending on product dimensions and material) and in prototype or full production volumes. The typical lead time for projects is two weeks or less after the mold is made.

In addition to our injection molding capabilities, we offer a variety of other manufacturing and finishing services, including:

- Transfer molding

- Insert molding

- Overmolding

- Heat transfer

- Ultrasonic welding

- Hot stamping

- Assembly

- Packaging

Examples of the types of components we can create include:

- Consumer goods (housings, children’s products, sporting goods)

- Electrical components

- Lab products

- Medical devices

- General industrial/OEM equipment

- And many more!

Why Partner With Daystar Manufacturing for Your Injection Molding Project?

Whether you’re looking for cosmetic or close tolerance components, Daystar Manufacturing can meet your plastic injection molding needs. By partnering with us, you benefit from our:

- Personalized approach. At the start of every project, we carefully evaluate the customer’s point of view and end-use. We use this information to develop a plan that suits their product needs and their project budget.

- We maintain an open line of communication with customers (defining the end-use, guiding them through the process, explaining the cost of the mold, etc.) to keep them in the loop throughout their project and ensure they understand their solution.

- Design and material expertise. We provide customers with design consulting and material selection assistance to ensure their injection molding solutions fully meet their specifications and standards.

- Competitive prices. We maintain low overhead, which allows us to provide our injection molding solutions at more competitive prices than larger companies.

- Commitment to quality. We remain extremely attentive to detail throughout customer projects to ensure we produce quality pieces. All products are subjected to in-process inspection after production and before packaging.

- Turnkey solutions. We provide complete turnkey solutions. In addition to our plastic injection molding capabilities, we offer plastic product design, mold making, prototyping, assembly, and many other manufacturing services to serve as a one-stop resource for molded component needs.

Get Started on Your Injection Molding Solution Today

Daystar Manufacturing is the ideal injection molding partner. Equipped with extensive hands-on molding experience and advanced molding technology, we have what it takes to deliver high-quality, cost-effective solutions for a wide range of injection molding projects. We can handle everything from part design to prototyping to mold making to production to assembly. Contact us today to learn more about our capabilities or discuss your project with one of our experts.